ENGINEERING

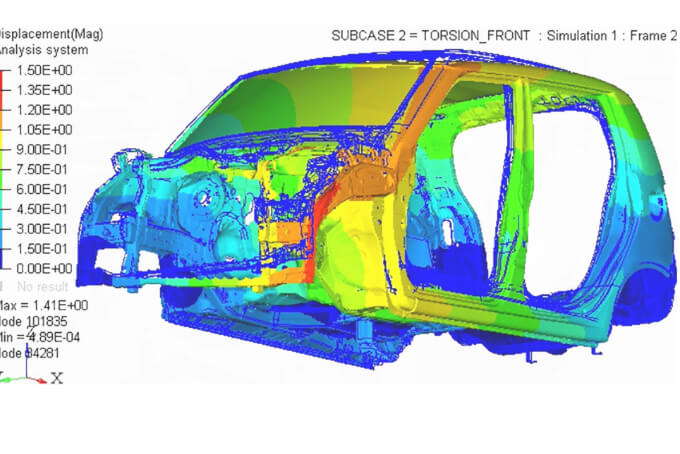

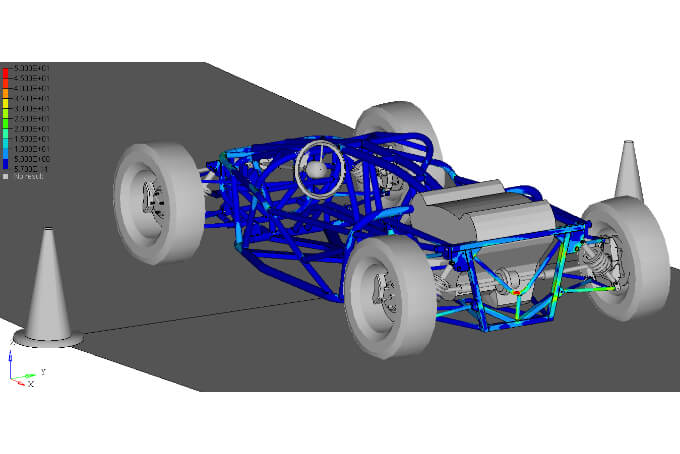

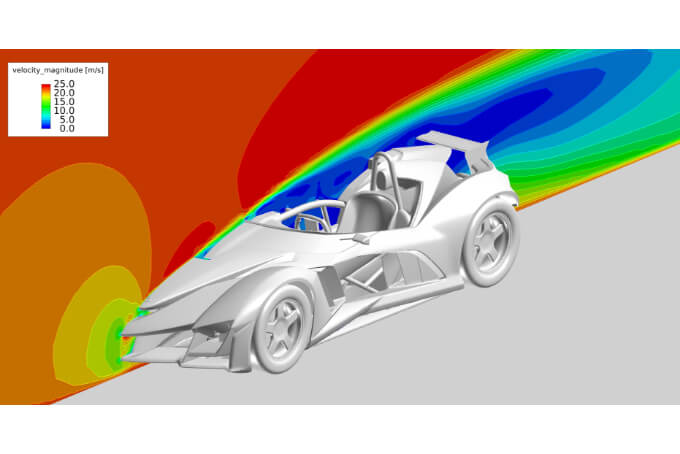

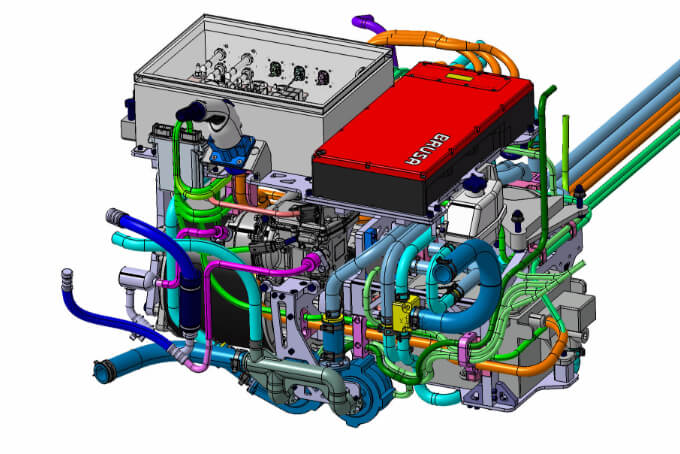

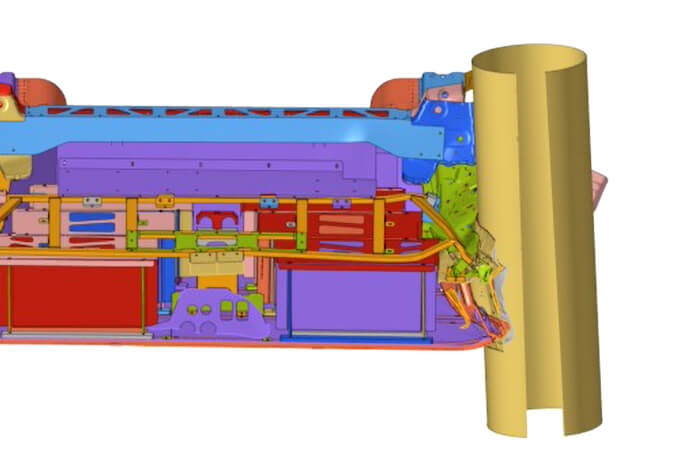

As the needs of our clients become more diverse and complex, so must our development become more efficient. That’s why we are actively utilizing new digital technologies such as model-based development in order to keep R&D costs to a minimum and bring new products to market more quickly. Our engineers, in cooperation with other departments as well as our clients, conduct various simulations in CAD from the earliest stages of development to meet a wide range of requirements such as function, design, durability, and cost.

Additionally, with the decline in demand for full-scale prototypes, our physical testing and evaluation is shifting to a focus on functionality and reproducibility. We also strongly believe that our commitment to a holistic approach to hardware and software development at Phiaro’s engineering department will become an increasingly important part of our success and the success of our clients.

Design/Analysis/Testing

- Packaging and Layout

- Exterior body development

- Interior trim development

- CAE simulation

- Design Optimization

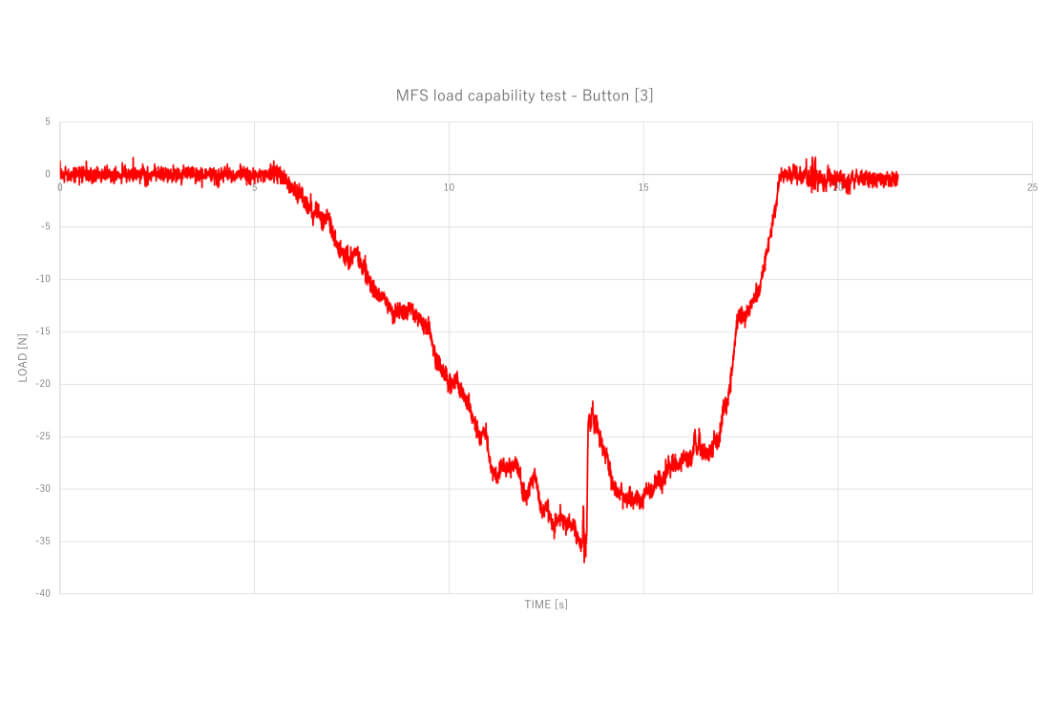

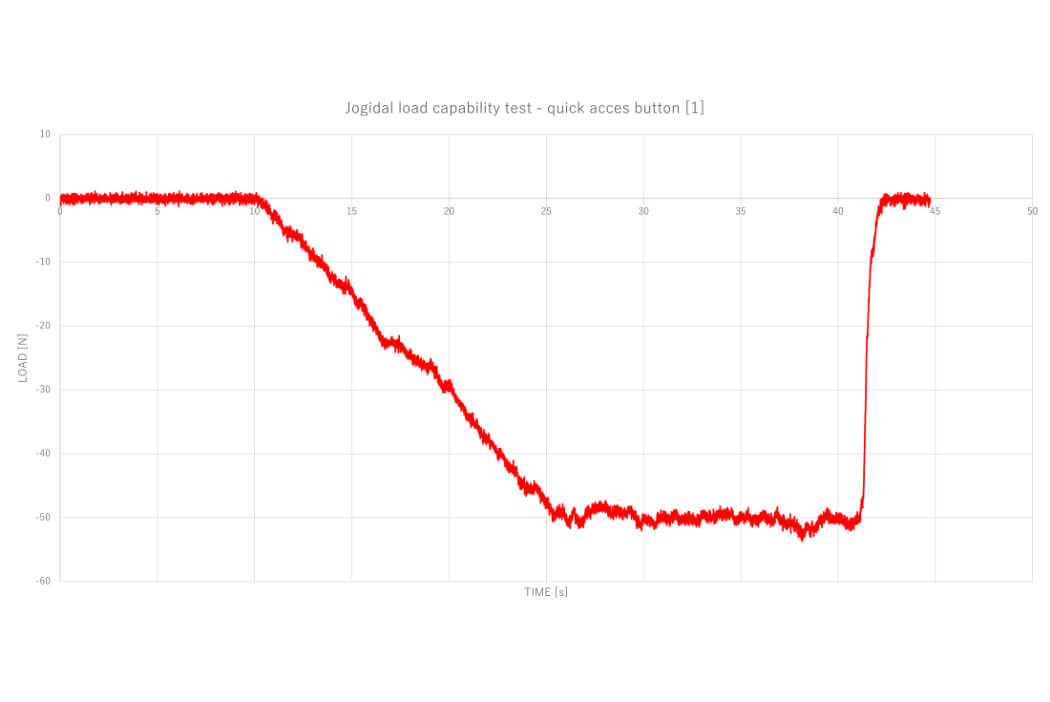

- Test and validation

Prototype construction

- Running prototypes

- Vehicle modification

- Various prototype parts production

- 3D printing technology

- Jigs and Fixtures

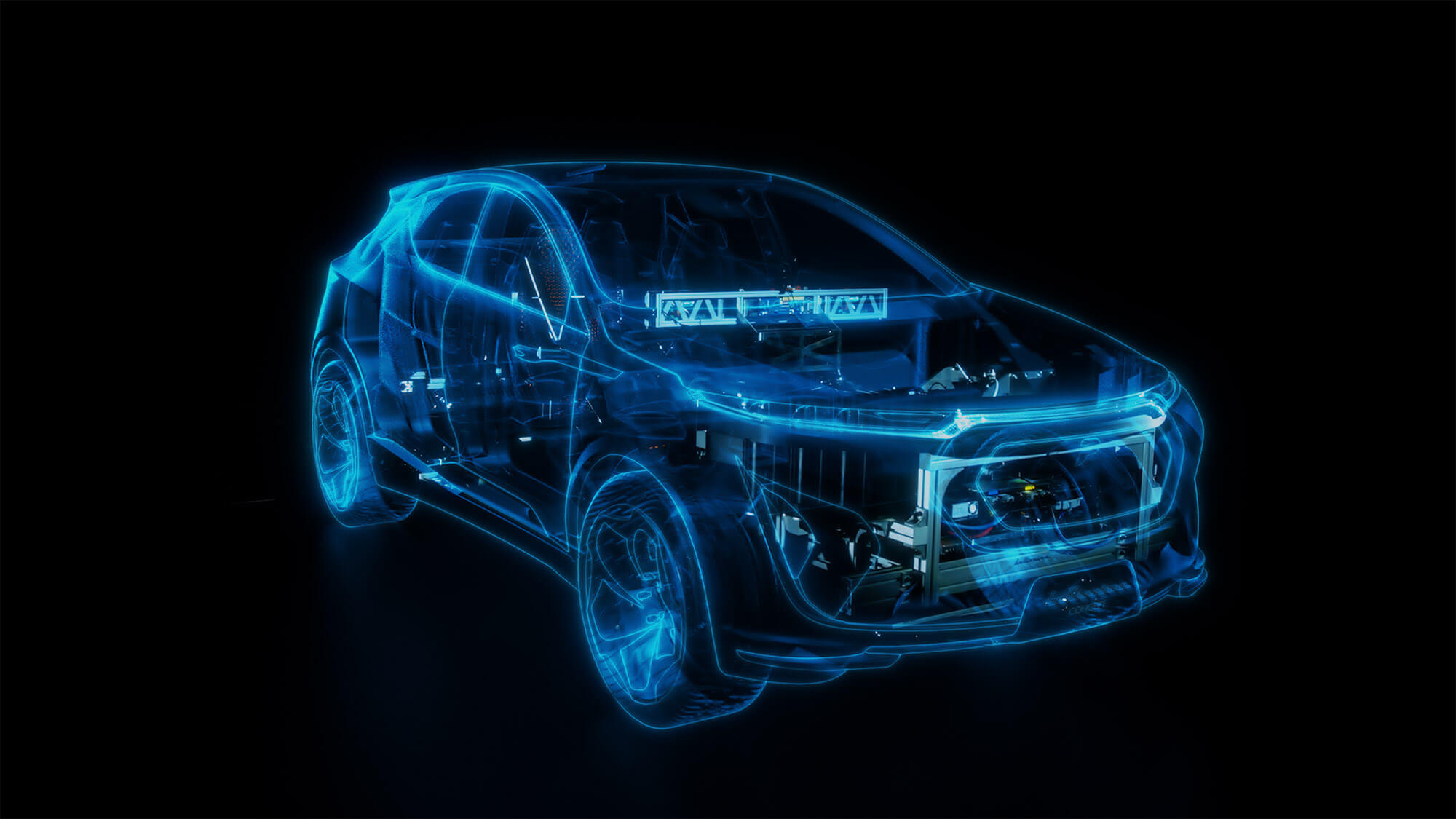

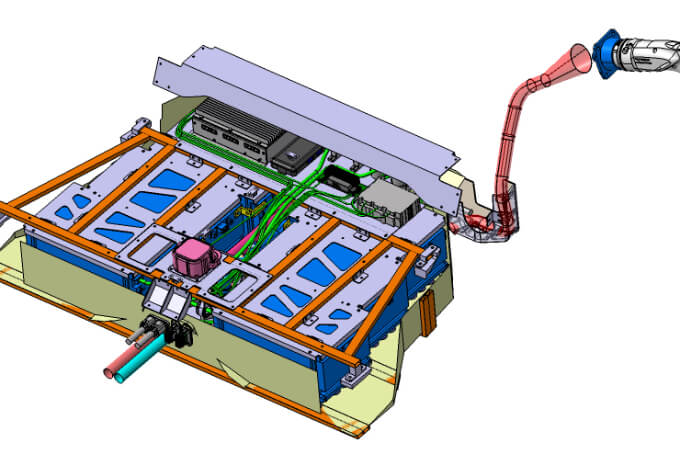

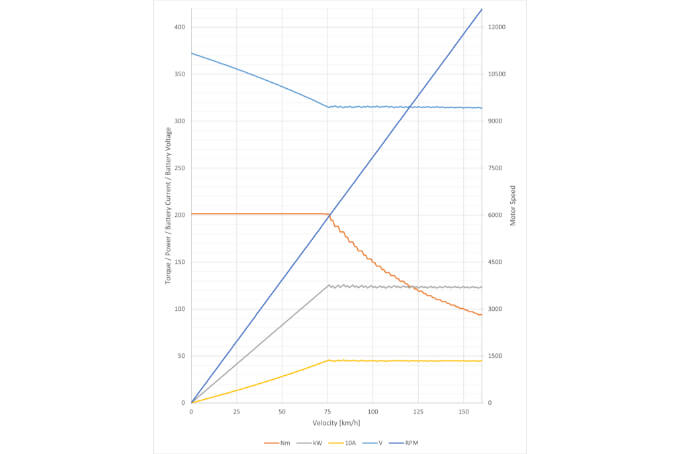

Electric Vehicle development

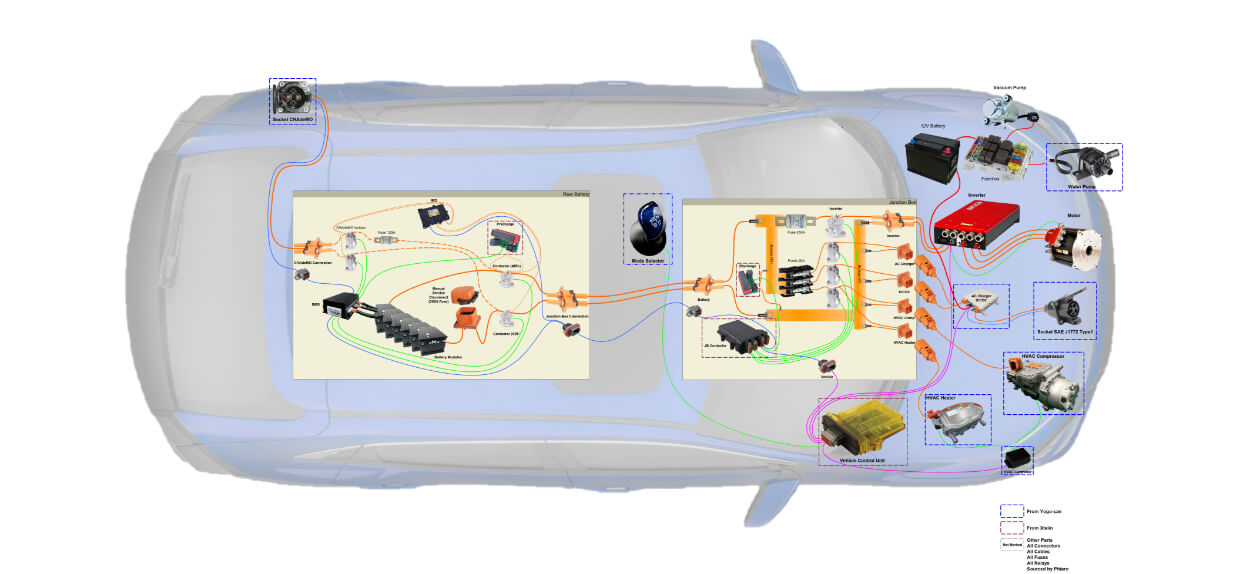

- High voltage system integration (motor, battery, on-board charger DC/DC-convertor, junction boxes HV cable, etc.)

- Low voltage system integration (power distribution and communication, wire harness, etc.)

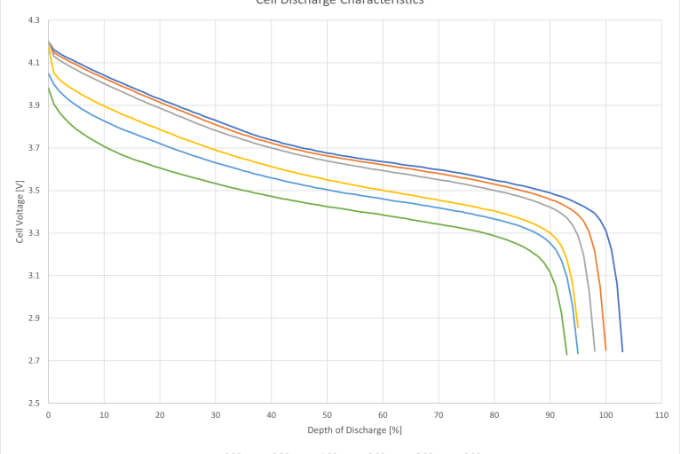

- Battery design (lithium battery and BMS)

- VCU development

- CAN-bus analysis and communication

- Electric and electronics drivetrain test bench

Electrical/

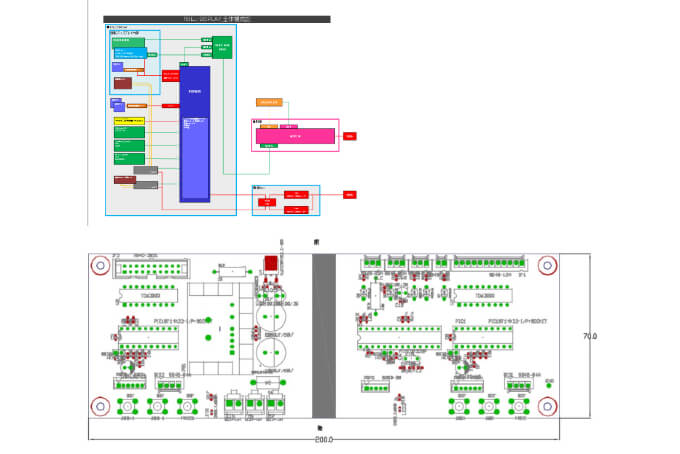

Electronics/

Embedded System Development

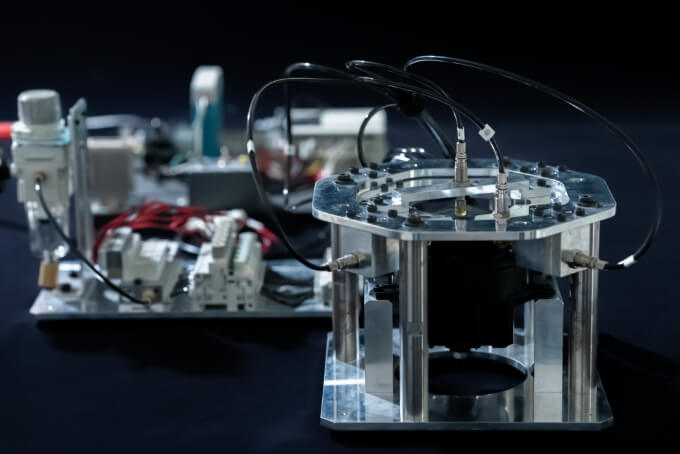

- Control Software Development.(PC based system, microcomputer, PLC, network communication system )

- Application Development(Windows / iOS / Android / Linux)

- Hardware Development(Microcontroller:PIC、PSoC、Arduino、Raspberry Pi、STM32 and Circuit Board making :Circuit Design、Board Design、Component Mounting)